A family run engineering fabrication firm in Caithness is investing in a project to improve productivity, grow business turnover and create new jobs.

Gow’s Lybster Limited has been working with development agency Highlands and Islands Enterprise (HIE) over several years to develop its growth plans.

This latest investment by the company comes after it secured two major new contracts from outwith the region. HIE has awarded more than £60,000 towards the total project costs of £243,000.

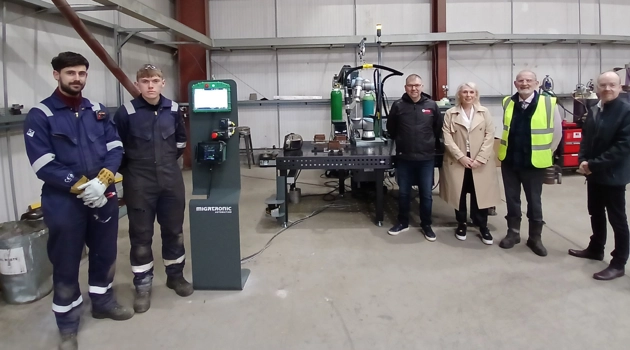

The funding will enable Gow’s to install two new high tech Migatronic CoWelders, or ‘cobots’. Capable of operating at pace around the clock and to high spec, these new machines will significantly improve productivity and ensure consistent high-quality workmanship.

The company will train some existing employees on the use of the cobots, while continuing to recruit apprentices to ensure a supply of trained welders coming into the business.

Over the next three years the increase in production capacity is expected to create four new full time equivalent jobs, boost annual turnover by around £1m and lead to more large-scale fabrication contract wins.

Hilary Budge senior development manager with HIE’s Caithness and Sutherland team said:

“Gow’s Lybster has been around for nearly twenty years and is an important part of the local economy, with specialist expertise in technology and advanced engineering. The company has done well to compete successfully for major contracts from outwith the area.

“This project will see the latest technology brought into the firm, improving productivity and quality, thereby strengthening its position to bid competitively for more large-scale contracts. The investment will help attract new talent, develop the engineering sector and diversify the local economy, which in turn will help benefit community resilience.

“I’m very pleased we’ve been able to support the project and look forward to continuing to work with the company.”

Wullie Robertson, managing director of Gow’s Lybster Limited, said:

“The introduction of new technologies along with the upskilling of our existing workforce and the recruitment of further apprentices will secure the company’s future manufacturing capability and capacity.

“The investment will allow us to secure further contracts from across the UK and to bring the manufacturing operations to Caithness. We very much welcome and appreciate HIE’s involvement in our success over the past 20 years.”